Graphite Oven Chain Lubricant

See pds for useful temperature range.

Graphite oven chain lubricant. Lubricants with graphite have good heat and excellent wear resistance. In most cases for bakery oven applications liquid graphite is applied manually to the chain with a kerosene or other hydrocarbon based carrier fluid. Although that blog related to bicycle chains where a dry lube is preferred in south africa it does raise the subject of graphite another great dry lubricant. Lubricants with ptfe can be used with most plastics and are chemically inert.

Bakerylube oven chain lubricant cold chain is graphite with a fluid carrier for use in ovens that are able to cycle down to temperatures below 82 c 180 f. If this lubricant was not applied on a regular weekly basis the chains would bind up which in turn tripped the main power for the oven and shut down production. Asbury graphite oven chain lubricants more bakers choose asbury graphite lubricants than any other brand. For more than 100 years bakeries and other industries have relied on asbury dixon and slip plate graphite oven chain lubricants to keep their equipment operating dependably extend the life of their oven chain and components.

Superflake hot oven chain hoc lubricant is designed with a unique natural graphite powder that offers superior lubricity even under extreme conditions. Water vapor in the air reduces molecular bonding of the graphite causing it to slip thereby reducing friction. The commercial grade lubricant in use had a graphite base was black and messy. The downside of graphite as a lubricant.

Unique oven chain lubricants made from mixtures of graphite powders and fluids designed to lubricate bakery oven chains at varying temperatures. They dry to form a film that lubricates without attracting dust. Because q20 is formulated as a multi purpose oil in some cases it s better to use a specialist product such as q5 which is a graphite based lubricant rather than a oil based product. Whereas this is an extremely flammable combustible liquid with a lower flashpoint typically below 160 f black graphite lubricant is generally applied manually to a cold oven.

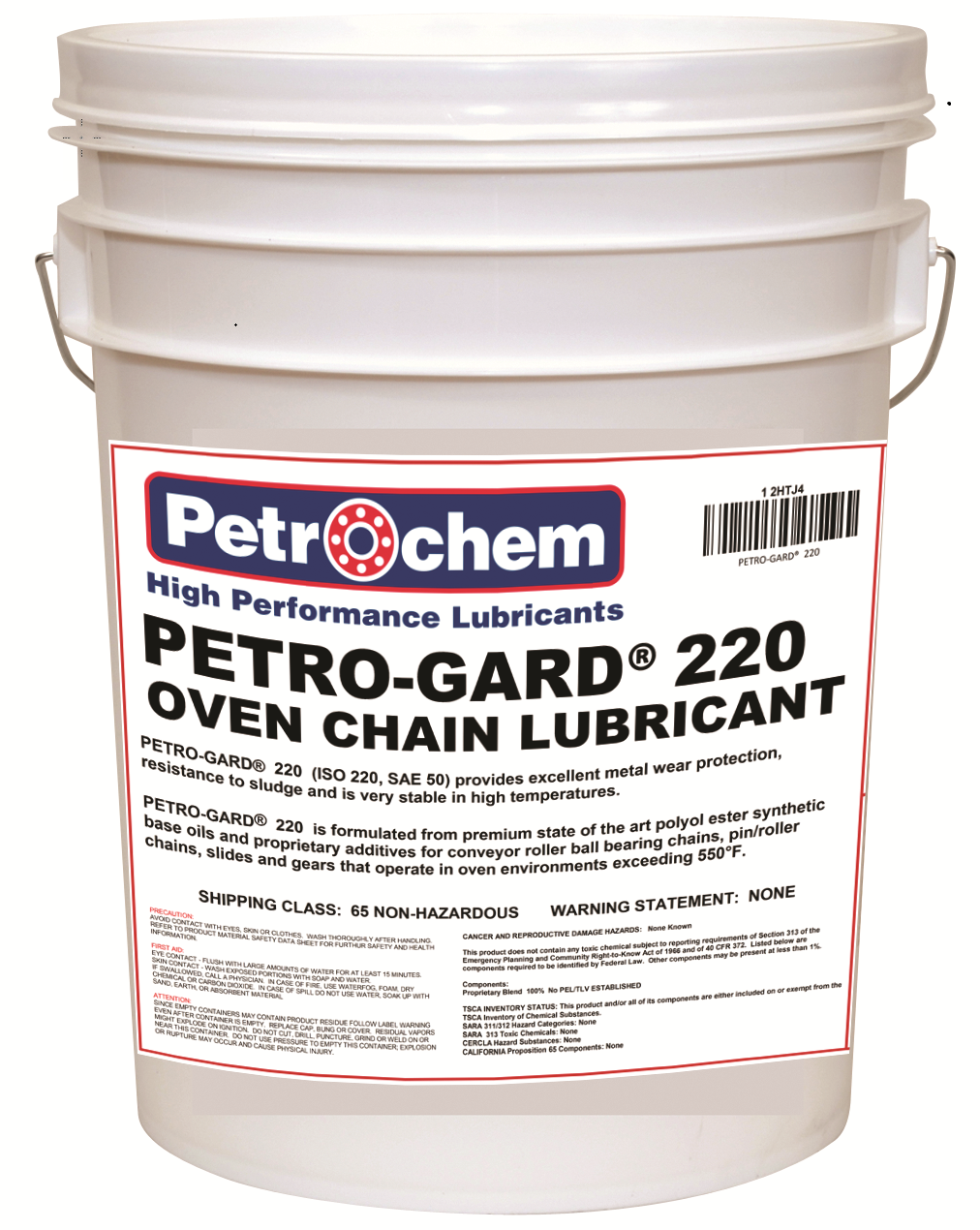

A usda h2 lubricant it contains a synergistic blend of lubricating solids including submicron sized almasol particles in a specially designed synthetic carrier fluid. Graphite as a dry lubricant requires atmospheric contact for optimal performance. A high load carrying capacity makes these lubricants good for use on chain and moving metal parts. One of its ovens has a chain drive kiln screen used in the baking process.